|

|

||||||||

|

|||||||||

Region of Research

Research Division of Materials Joining Mechanism |

|||||

|

Welded or joined structures are widely used in a variety of industries, which support sustainable growth of our society. Expanding applications increase the demands for higher performance and reliability upon the welded and joined materials including dissimilar joints.

|

||||

Research Division of Materials Joining Assessment |

||||

|

The promotion of the science and technology for manufacturing high-quality products and building durable structures leads to the innovative and sustainable growth of industries. The joining/welding design emphasizes the increasing need for a methodology to predict the structural performance and integrity from a stage of designing structures with the best use of materials. The Research Division of Materials Joining Assessment consists of three Departments; Joining Mechanics and Analyses, Joining Design and Structuring, and JJoining Metallurgical Evaluation, aiming at the creation of an interactive design system eligible for structural performance assessments in service conditions. Each Department deals with the simulation of joining & welding construction with computational technologies, ,development of design methods for strength and reliability of structures considering mechanical effects of welding and joining, and the reliability evaluation of welded joints in terms of materials science, respectively.

|

|||

Research Center for Additive Joining Application (RAJA) |

|||||||

|

The Research Center for Additive Joining Application (RAJA) is established as a research organization in the Joining and Welding Research Institute (JWRI) on 1st April 2022 via the reorganization of the former Smart Processing Research Center. The primary objective of the RAJA is to investigate successive joining and welding phenomena in novel additive manufacturing (AM) processes. Practical applications of functional components of metals and ceramics with modulated structures should be actively and promptly realized in future industrial fields.

|

||||||

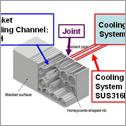

Joint Interface Microstructure Characterization Room |

|||

|

|

||

Global D&I Promotion Office |

|||

|

|

||

Research Alliance Laboratories / Division of Joint Research Chair |

||||||

|

|

|||||

Strategy Office for Promotion of Inter-Institute Collaborations |

||

|

|

|

New Normal Manufacturing Consortium Office |

||

|

|

|

International and Industry-academia Joint Research Center |

||||

|

|

|||

Our Researches